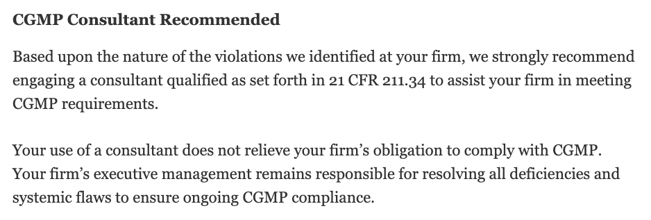

Many FDA Warning Letters include the same three-word phrase toward the end of the letter: “CGMP Consultant Recommended.”

This line is almost always followed by the following statements:

“Based upon the nature of the violations we identified at your firm, we strongly recommend engaging consultants qualified as set forth in 21 CFR 211.34, to assist your firm in meeting CGMP requirements.” “Your use of consultants does not relieve your firm’s obligation to comply with CGMP. Your firm’s executive management remains responsible for fully resolving all deficiencies and ensuring ongoing CGMP compliance.” |

Here's an excerpt from an actual Warning Letter:

Then, depending on the nature of the problems FDA observed and cited in its letter, the following statements may also appear:

“The qualified consultant should perform a comprehensive audit of your entire operation for CGMP compliance and that the consultant evaluates the completion and effectiveness of your corrective actions and preventive actions before you pursue resolution of your firm’s compliance status with FDA.” “If you still plan to manufacture drugs, we also recommend a qualified consultant with drug manufacturing experience perform a comprehensive audit of your drug production operation for CGMP compliance and evaluate the completeness and effectiveness of any CAPA you have implemented before engaging in drug production." |

Since we’re the consulting firm many FDA-regulated companies engage when they need a CGMP consultant—whether it’s in response to a Warning Letter or as part of its proactive compliance assurance/auditing program—we thought we’d provide a basic summary of what to consider and what actions to take if you find yourself in need.

If you’ve received a Warning Letter recommending you engage with a qualified CGMP consultant, or if you’re looking to prevent such a situation, get in touch using our contact form as soon as possible.

We've helped thousands of companies quickly and diligently access the third-party assistance they need to address compliance issues and manage remediation as well as communication with regulators.

📄 For a more comprehensive guide to Warning Letter response, read our free white paper: The Emergency Guide to FDA Warning Letters & FDA Form 483.

The Emergency Guide to FDA Warning Letters & FDA 483

Learn the key steps to take after receiving an FDA Warning Letter or FDA 483, including the key elements of CAPA, crafting an effective response, and how and when to tap the assistance of third-party experts.

Understanding Why FDA Recommends Consultants

It’s important to acknowledge that when FDA explicitly directs a company to get help from an outside expert, it means that the investigator—or team of investigators—not only observed significant deficiencies but determined that the company’s internal staff did not demonstrate the competencies, discipline, resource bandwidth, and/or culture of quality to remediate and prevent the recurrence of those deficiencies on its own.

While resolving the acute deficiencies that precipitated the issuance of a Warning Letter is the priority, this broader, implicit indictment should give Quality teams pause. It should trigger serious, thoughtful introspection and prompt teams to soberly identify, articulate, and confront the underlying deficiencies that led regulators to express a lack of faith in the team’s abilities to fix its own problems.

Although there’s no handy playbook for doing this kind of fundamental assessment in competency or capability since one situation may vary wildly from the next, FDA is quite clear about what they expect from the Quality Unit.

We summarized some of the most important of these expectations in another blog post if you're interested. An honest comparison of the team’s current competencies and capacities against these documented expectations is a smart first step in addressing an under-resourced Quality Unit.

The 2006 final guidance, Quality Systems Approach to Pharmaceutical CGMP Regulations, describes what, specifically, FDA expects from the Quality Unit. Any firm FDA instructs to work with outside consultants to remediate deficiencies should closely review the entire guidance and identify any expectations that aren’t met—and then work to meet them (ideally with a consultant's help and invaluable outside perspective).

Here are just a few of the stand-out expectations from the “Personnel Development” section of guidance that can be instructive in this context:

|

Again, this is by no means an exhaustive list. If you’re looking for improvements to your Quality Unit, read the entire guidance, highlight every expectation offered, and phrase them as a question for honest, internal assessment.

- "Are our staff qualified to do every operation that is assigned to them? If so, how can we demonstrate it?"

- Is senior management supporting a problem-solving and communicative organizational culture? If so, how can we demonstrate it?"

- Are we providing continued training that ensures our staff remains proficient in their operational functions and in their understanding of CGMP regulations? If so, how can we demonstrate it?"

If you find gaps in any areas of expectation, we can help you deploy consultants, augment your team with full-time contractors, and/or supply FTE candidates to help or personally fulfill those needs. Contact us.

FDA’s Expectations for a “Qualified” CGMP Consultant

Conveniently, FDA points to 21 CFR 211.34 when calling firms to work with a qualified consultant. Here it is:

211.34 Consultants.

Consultants advising on the manufacture, processing, packing, or holding of drug products shall have sufficient education, training, and experience, or any combination thereof, to advise on the subject for which they are retained. Records shall be maintained stating the name, address, and qualifications of any consultants and the type of service they provide.

So, the regulation calls for consultants to have enough education, training, and/or experience to advise on what they've been hired to do.

Here at The FDA Group, we give teams access to a massive network of qualified professionals with demonstrable knowledge, training, and experience across the entire landscape of CGMP compliance issues within FDA-regulated industries. Records of these qualifications for each of our consultants are maintained and are available for review as required by 21 CFR 211.34.

You can use our consultant finder search tool to browse a sample of our network and see a few blinded CVs for yourself.

What to Look for in a CGMP Consulting Firm

Without the right resourcing partner (one that can take on the intensive work of finding talent and qualifying candidates around precise requirements), finding qualified CGMP consultants under the pressure of a Warning Letter can demand significant time and energy—with the risk of a wrong fit.

Here are 3 useful, but often-overlooked tips when looking for a life science consulting partner that can help you find exactly who need, when and where you need them.

Read more about all of these points in our other post. And read our other post on contracting with life science consultants here.

1. Specific life science expertise

Consulting firms that work across a variety of industries often dilute their effectiveness in each one. Is the firm full of generalists or do they live and breathe life science?

The core issue here is that the recruiters within massive, multi-vertical firms are often generalists. Unlike a niche firm, whose recruiters must bring deep industry-specific experience to be successful, generalists often don’t have the firsthand subject matter expertise to understand and articulate the fine points about the roles, functions, and subject matter expertise that qualify a consultant for a particular project and guide the search and selection process.

Here at The FDA Group, our recruiters and project managers come from the world they hire into each day. Unlike larger firms, we’re armed with firsthand experience working in the roles where the subtle details make all the difference—accelerating the process of finding great talent.

2. An effective talent search and selection process

Ask about their search process. How do they identify right-fit consultants?

Especially in specialized life science roles, the job of a resourcing firm is to identify genuinely perfect-fit talent—not simply pass a stack of resumes for you to do that. Investigate how the firm finds and selects the resources they deliver as consultants and/or candidates.

- What methods do they use to apply your requirements to identify the right consultant?

- Equally if not more importantly: how do they sift through that group and work it down to a shortlist of extremely qualified candidates you can be confident in?

Using ourselves as the example again, we have a large network of people with established consulting agreements with our firm—some of whom are former FDA staff with intimate knowledge of requirements and expectations. If for some reason the perfect resource isn’t found there, we immediately move to an active channel to source from many thousands more in locations all around the world.

2. Experience supplying CGMP consultants for others

Gauge their experience level with this type of project. Do they have what it takes to provide you with the specific expert you need?

Experience level often ties in closely to generalist versus niche resourcing firms.

- Are the recruiters being tasked with finding a very specific technical skillset fresh out of college and trying to find their stride professionally?

- Do they actually know the industry terms they’re working with?

This is a simple, but crucial point that often flies under the radar only to result in a messy stack of candidates that might be laughably far from what you actually need. More resumes/CVs don’t mean better consultants.

Get the right consultant the first time—wherever and whenever you need them.

Need to access a qualified CGMP consultant? We give you access to dedicated life science professionals with the experience, skills, and background to see your project through to success.

Whether you need a single resource or an entire team of on-site or remote resources, we connect you to qualified life science specialists to build, scale, and efficiently manage projects through traditional direct hire recruiting as well as a flexible contract staffing/staff augmentation model that better reflects cyclical or project-based demand while infusing new skills and experiences into your team.

We fully understand your resourcing needs and employ our proprietary talent selection process to provide the resources you need, at a competitive rate, with dedicated account management every step of the way. All of our services are backed by a Total Quality Guarantee.

Contact us and get the conversation started or grab our free white paper below to learn more about addressing a Warning Letter.