Three-dimensional printing is revolutionizing the way medical conditions are treated. These printers are able to create customized medical devices and other medical products for patients.

Moreover, this new market is open to any manufacturer, not just medical device companies. Therefore, manufacturers should understand the trends associated with this growing use of technology.

Potential Uses for Three-Dimensional Printers in the Pharmaceutical Industry

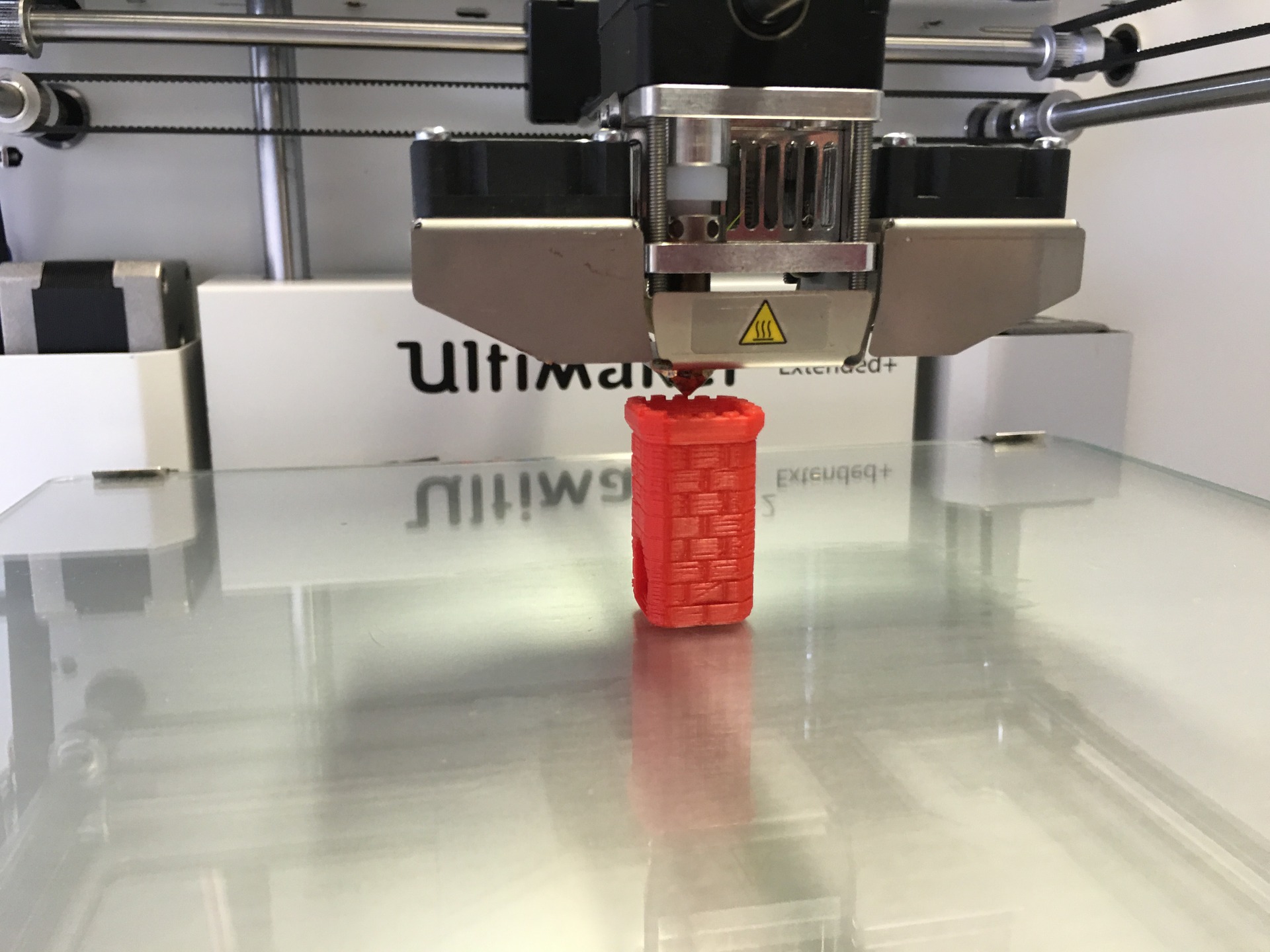

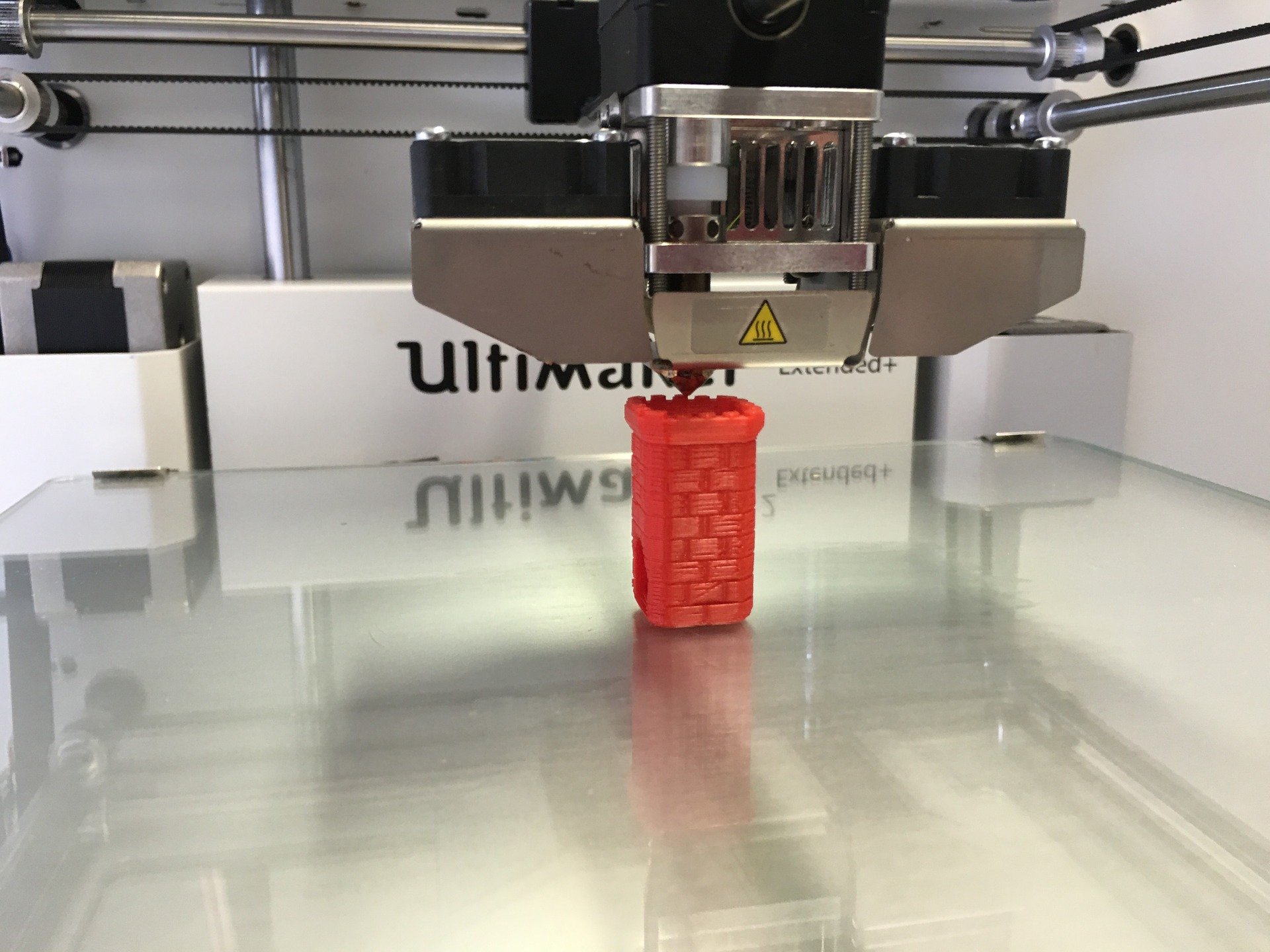

Three-dimensional printing is a technique in which manufacturers use a printer to make medical devices and other products from blueprints stored in a computer.

This enables them to create low-cost devices custom made for a particular patient in real time. Some examples include implants to replace the parts of a patient's skull or customized hearing aids.

Researchers have also been able to generate embryonic stem cells, blood vessels, cardiac tissue, skin, stem cells that could grow into bone and cartilage, and cells that can repair damaged cardiac tissue. Although not a reality at present, three-dimensional printers may one day generate organs such as kidneys, thereby eliminating the need for organ transplants.

At a recent workshop sponsored by the Food and Drug Administration, practitioners also demonstrated how cardiac models printed with the three-dimensional printer could influence clinical decision making and patient care, reducing operating costs. As such, three-dimensional printers have the potential to change dramatically the way health care practitioners treat conditions.

There have been some concerns regarding the regulation of these devices and products. For instance, some critics say that with this new technology almost anyone could make a medical device or product, which might make these products difficult to regulate.

Similarly, techniques for sterilizing devices generated with three-dimensional printers might not be as standardized or effective as practices for manufacturing other devices.